Examples of my scientific work

Monodisperse PMMA-beads as a model for DWBA effects

Two samples with the same PMMA-beads were compared by means of GISAXS: A) with a loose package of beads and B) with compact arrangment. Both are monolayers and have the same bead diameter of 340 nm. The following figure shows the two different situations, how the x-ray beam (red) passes the particles and which scattering terms (yellow) will appear. In the upper case all four terms are possible. While term 1 has its orign around the direct beam, the other two strong terms 2 and 3 will scatter around the reflected beam. This will lead to a strong oszillating scattering around the specular beamstop, with interferences between term 2 and 3, as they have a slightly phase shift.

DWBA scattering events for a loose (top) and a dense arrangement (bottom) of relatively large PMMA-beads on a highly reflecting silicon substrate

DWBA scattering events for a loose (top) and a dense arrangement (bottom) of relatively large PMMA-beads on a highly reflecting silicon substrate

I used these models for simulating GISAXS scattering patterns and compared them with a GIUSAXS experiment. The simulation and experiment are in good agreement. Most of the maxima in the patterns arise from the form factor terms, and not from the 2D-lattice.

Experiment and simulation for a loose (top) and a dense arrangement (bottom) of PMMA-bead monolayers)

Experiment and simulation for a loose (top) and a dense arrangement (bottom) of PMMA-bead monolayers)

(click images for original publication)

Filled block copolymer micelles and plasma treatment

The next experiment show patterns and simulations for SiO2 loaded cores in a micellar monolayer before and after plasma treatment. Assuming the depicted model of core/shell spheres or half spheres on a substrate the simulation leads to almost identical patterns. This allows determining the lateral distances between the particles. Additionally the height, shape, and density of the particles are revealed as well as the all over thickness of the coating. Before plasma treatment, the still existing polymer scatters at a lower critical angle than the substrate, which leads to an additional scattering maximum at lower qz. Hence the polymer shell has the same lateral periodicity as the filled cores, the reflections along qy do not change their position. Before O2 plasma treatment, the 2-dimensional hexagonal array has a period of 38.5 nm, the SiO2 particle radius is 9 nm and the height of the coating 22 nm. After removing the organic shell via oxygen plasma the height of the array decreases to 13 nm, while the lateral values are constant. This means that not only the organic shell on top of the SiO2 particles is completely removed but also the particles are etched from the top by 5 nm.

Experiment and simulation before and after O2-plasma treatment of SiO2 filled diblock copolymer micelles on a silicon wafer

Experiment and simulation before and after O2-plasma treatment of SiO2 filled diblock copolymer micelles on a silicon wafer

The microscopic methods SEM and AFM are not suitable to investigate the surface morphology on the scale of several mm. Micrographs show only a small part of the sample and for better statistics additional methods are needed. Here GISAXS is the first choice, as it reveals information from a large part (several mm2) of the surface. The scattering curves can be compared with the FFTs of the microscopic images, to demonstrate that the same nanostructure is uniformly spread over a large surface area.

SEM FFT spectra and GISAXS out of plane scattering curves (at Yoneda maximum) from silica filled micelles before and after O2-plasma etching

SEM FFT spectra and GISAXS out of plane scattering curves (at Yoneda maximum) from silica filled micelles before and after O2-plasma etching

(click images for original publication)

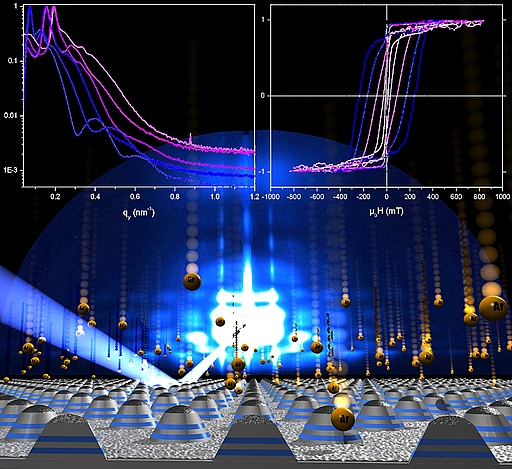

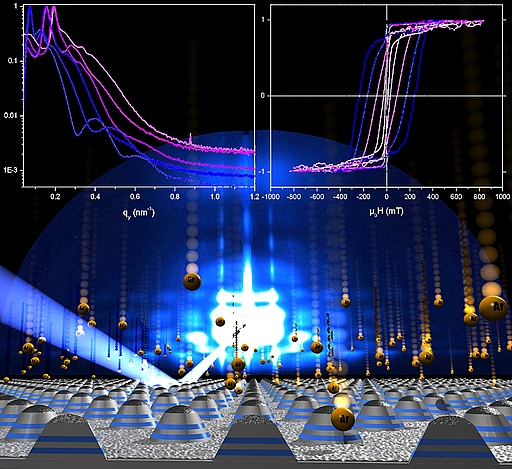

In-Situ GISAXS of Block Copolymer Templated Formation of Magnetic Nanodot Arrays and their Magnetic Properties

Two-dimensional arrays of magnetic nanostructures are created using silica filled diblock copolymer micelles as templates. After self-assembly of the micelles into 2D-hexagonal arrays, the polymer shell is removed and the SiO2-cores are utilized to transfer the morphology into a (Co/Pt)2-multilayer via ion etching under normal incidence. The generated dots were made of (Co/Pt)2-multilayers. High resolution in-situ GISAXS investigations are performed during Ar+- ion etching to monitor and control the fabrication process. The in-situ investigation gives information how to improve the etching conditions for further ex-situ experiments. The GISAXS patterns are compared with simulations. We find that the dots change its shape from cylindrical to conical during the etching process. The magnetic behavior is studied utilizing MOKE (magneto-optic Kerr effect). The Co/Pt dots exhibit different magnetic behavior, depending on their size, interparticle distance and etching time. They show ferromagnetism with an easy-axis of magnetization perpendicular to the film. A systematic dependence of coercivity on dot size is observed.

Illustration of the in-situ GISAXS experiment during Ar+-ion milling and resulting GISAXS and MOKE curves (insets)

Illustration of the in-situ GISAXS experiment during Ar+-ion milling and resulting GISAXS and MOKE curves (insets)

Below, GISAXS patterns during the Ar+-ion etching process are presented. Horizontal lines indicate the critical scattering angles of SiO2 (grey) and platinum (green). Dotted lines show diffuse form factor scattering of the conical angle evolution which corresponds to the schematic inset in the upper left for each row. One can observe that the maximum qz-scattering (Yoneda-peak) moves to lower values during etching time, due to the removal of the platinum. Synchronous, the vertical oscillations of the multilayer move up and outwards of the detector, as layers are getting thinner. The dot shape changes from spherical at the beginning, over cylindrical to a conical form factor and remains constant for times larger than 320 s.

In-situ GISAXS patterns during Ar+-ion etching of a magnetic multilayer substrate, covered with a silica dot mask and changing form factor (inset).

In-situ GISAXS patterns during Ar+-ion etching of a magnetic multilayer substrate, covered with a silica dot mask and changing form factor (inset).

(click images for original publication)

Thermal ligand degradation at CoPt3-nanoparticles and their arrangement in monolayers

After deposition of 10 nm sized CoPt3-nanoparticles on a silicon substrate, the particles self assemble into highly ordered 2-dimensional hexagonal arrays. The organic shell prevents the interparticle contact. To remove the organic ligands, the samples were heated to different temperatures for 2 hours. The stability of the particles and of the 2-dimensional arrangement is important for further applications, i.e. magnetic quantum dots.

Thermal degradation of a 2D nanoparticle array at different temperatures.

Thermal degradation of a 2D nanoparticle array at different temperatures.

left: GISAXS patterns; mid: intensity profile cuts along q

y and Scatter simulation with parameters; right: SEM images (200 nm x 200 nm; 20 keV)

(click image for original publication)

At 300 °C the interparticle distance decreases, while the quality of the array is constant. At higher temperatures, the particles start to melt and form partial aggregates, which lead to a higher deviation of the particle form factor. Additionally the diffuse scattering increases and the order parameters show a stronger displacement of the particles from their ideal lattice points.

![]()

![]() DWBA scattering events for a loose (top) and a dense arrangement (bottom) of relatively large PMMA-beads on a highly reflecting silicon substrate

DWBA scattering events for a loose (top) and a dense arrangement (bottom) of relatively large PMMA-beads on a highly reflecting silicon substrate![]()

![]() Experiment and simulation for a loose (top) and a dense arrangement (bottom) of PMMA-bead monolayers)

Experiment and simulation for a loose (top) and a dense arrangement (bottom) of PMMA-bead monolayers)![]() Experiment and simulation before and after O

Experiment and simulation before and after O![]() SEM FFT spectra and GISAXS out of plane scattering curves (at Yoneda maximum) from silica filled micelles before and after O

SEM FFT spectra and GISAXS out of plane scattering curves (at Yoneda maximum) from silica filled micelles before and after O![]() Illustration of the in-situ GISAXS experiment during Ar

Illustration of the in-situ GISAXS experiment during Ar![]() In-situ GISAXS patterns during Ar

In-situ GISAXS patterns during Ar![]() Thermal degradation of a 2D nanoparticle array at different temperatures.

Thermal degradation of a 2D nanoparticle array at different temperatures.